All Products

-

Cold Rolled Stainless Steel Sheet

-

Seamless SS Pipe

-

Stainless Steel Coil

-

Stainless Steel Round Bar

-

Galvanized Steel Pipe

-

Galvanized Steel Coils

-

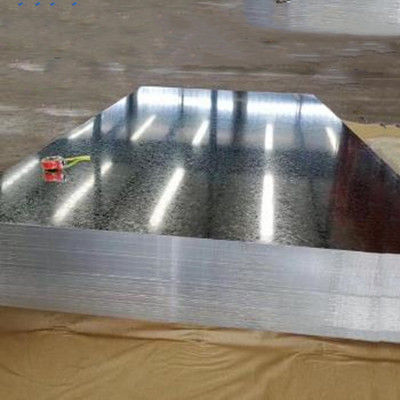

Galvanized Steel Sheet

-

PPGI Steel Coils

-

Steel Tin Plate

-

Mild Steel Square Tube

-

Carbon Steel Coils

-

Carbon Steel Sheets

-

Wear Resistant Steel Plates

-

Aluminum Steel Sheet

-

Copper Steel Pipe

-

Copper Steel Bar

-

Copper Sheet Coil

-

Structural Steel Profiles

-

John Fairbankstainless steel strip with good quality and the Sales clerk service is very good.i like this company i hope can work with your again

John Fairbankstainless steel strip with good quality and the Sales clerk service is very good.i like this company i hope can work with your again -

Harish kumarأنا راضٍ جدًا عن هذه الصفقة ، ليس فقط لأنهم يشحنون بسرعة ، ولكن أيضًا جودة البضائع جيدة ، وأتطلع إلى التعاون التالي.

Harish kumarأنا راضٍ جدًا عن هذه الصفقة ، ليس فقط لأنهم يشحنون بسرعة ، ولكن أيضًا جودة البضائع جيدة ، وأتطلع إلى التعاون التالي. -

RickyCooperate with a trial order. The service is excellent and the price is very good. Product quality is guaranteed and can stand inspection

RickyCooperate with a trial order. The service is excellent and the price is very good. Product quality is guaranteed and can stand inspection

Contact Person :

Ava

Phone Number :

0086 18706170710

Whatsapp :

+8618706170710

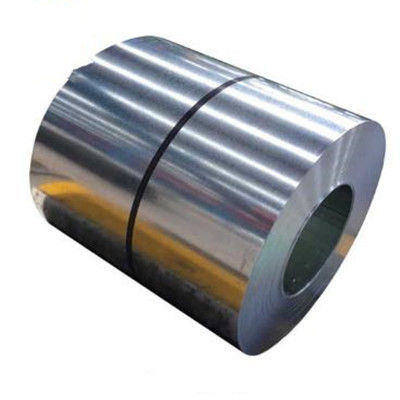

0.12-6.0 Mm DX51D Z40 Zinc Coating Quality Galvanized Steel Coil

| Place of Origin | CHINA |

|---|---|

| Brand Name | OEM/ODM |

| Certification | ISO |

| Model Number | SGCC |

| Minimum Order Quantity | 2 tons |

| Price | negotiable based on the quantity |

| Packaging Details | Standard seaport packing or as the custom request |

| Delivery Time | within 10 days after received the advance |

| Payment Terms | T/T, Western Union, L/C |

| Supply Ability | 1000 tons per month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

xProduct Details

| Zinc Coating | 30-275g/m2 | Color | Silver |

|---|---|---|---|

| Width | 30mm To 1250mm, 30mm To 1250mm | Thickness | 0.12-6.0 Mm |

| Spangle | Big,Regular,Small,Zero | Coil Weight | 3-8MT/Coil Or As Your Request |

| Application | Gutters ,Auto Parts ,Electrical Appliances,Purling, Vending Machine,Refrigerator,Ovens,For Prepainted ,Roof Sheet | ||

| High Light | 6.0mm thickness Galvanized Steel Coil,Zinc Coating Galvanized Steel Coil,gi steel coil |

||

Product Description

0.12-6.0 Mm DX51D Z40 Zinc Coating Quality Galvanized Steel Coil

|

Standard

|

AISI, ASTM, BS, DIN, GB, JIS

|

|

Type

|

Hot Dipped

|

|

Surface

|

Galvanized Coated

|

|

Surface Structure

|

Normal spangle coating(NS), minimized spangle coating(MS), spangle-free(FS)

|

|

Zinc Coating

|

15-275g/m2

|

|

Thickness

|

0.12mm-4.0mm

|

|

Width

|

600mm-1250mm

|

|

Coil Weight

|

3-5 Tons or Required

|

|

Coil ID

|

508mm/610mm

|

|

Coating

|

PE/PVDF/HDP/SMP

|

|

Top Painting

|

10-35 Microns

|

|

Back Painting

|

5-35 Microns

|

|

MOQ

|

25 Tons(1 20ft FCL)

|

|

Payment Term

|

T/T(30% Deposit+70% )

|

Product Introduction

Hot-dip galvanizing is the reaction of molten metal with an iron substrate to produce an alloy layer, thereby combining the substrate and the plating layer. Hot-dip galvanizing is to pickle iron and steel parts first. In order to remove iron oxide on the surface of iron and steel parts, after pickling, it is cleaned in an ammonium chloride or zinc chloride aqueous solution or a mixed solution of ammonium chloride and zinc chloride.And then sent to the hot-dip plating bath. Hot-dip galvanizing has the advantages of uniform coating, strong adhesion and long service life.

Galvanized Category

Hot dip galvanizing (HDGI):it is one of the common galvanizing methods. The process is to completely dip iron or steel into molten zinc.

Electro-galvanizing(EGI):it is to remove the oil, pickle, and then put into the solution of zinc salt by electrolysis equipment, and connect the negative electrode of the electrolysis equipment, place the zinc plate on the opposite side of the pipe fitting, and connect When the positive electrode of the electrolysis device is turned on, a layer of zinc is deposited on the pipe by the directional movement of the current from the positive electrode to the negative electrode, and the cold-plated pipe member is processed and then galvanized.

Electro-galvanizing(EGI):it is to remove the oil, pickle, and then put into the solution of zinc salt by electrolysis equipment, and connect the negative electrode of the electrolysis equipment, place the zinc plate on the opposite side of the pipe fitting, and connect When the positive electrode of the electrolysis device is turned on, a layer of zinc is deposited on the pipe by the directional movement of the current from the positive electrode to the negative electrode, and the cold-plated pipe member is processed and then galvanized.

Main Features Of Products

01.Anticorrosive:13 years in heavy industrial areas,50 years in the ocean,104 years in the suburbs and 30 years in cities.

02.Cheap:The cost of hot-dip galvanizing is lower than that of other coatings.

03.Reliable:The zinc coating is metallurgically bonded to the steel and forms part of the steel surface,so the coating is more durable.

04.Strong toughness:The galvanized layer forms a special metallurgical structure that can withstand mechanical damage during transportation and use.

05.Comprehensive protection:Every part of the plated piece can be galvanized,and is fully protected even in depressions,sharp corners,and hidden places.

06.Save time and energy:Galvanizing process is faster than other coating methods.

02.Cheap:The cost of hot-dip galvanizing is lower than that of other coatings.

03.Reliable:The zinc coating is metallurgically bonded to the steel and forms part of the steel surface,so the coating is more durable.

04.Strong toughness:The galvanized layer forms a special metallurgical structure that can withstand mechanical damage during transportation and use.

05.Comprehensive protection:Every part of the plated piece can be galvanized,and is fully protected even in depressions,sharp corners,and hidden places.

06.Save time and energy:Galvanizing process is faster than other coating methods.

![]()

![]()

![]()

![]()

Recommended Products