About Us

All Products

-

Cold Rolled Stainless Steel Sheet

-

Seamless SS Pipe

-

Stainless Steel Coil

-

Stainless Steel Round Bar

-

Galvanized Steel Pipe

-

Galvanized Steel Coils

-

Galvanized Steel Sheet

-

PPGI Steel Coils

-

Steel Tin Plate

-

Mild Steel Square Tube

-

Carbon Steel Coils

-

Carbon Steel Sheets

-

Wear Resistant Steel Plates

-

Aluminum Steel Sheet

-

Copper Steel Pipe

-

Copper Steel Bar

-

Copper Sheet Coil

-

Structural Steel Profiles

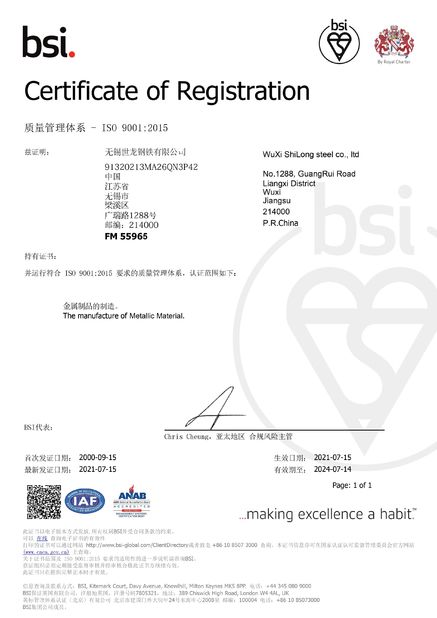

QC Profile

Quality Goal:

1. The passing rate reach 100%

2. Customer satisfaction rate over 90%

Quality Control Measures:

According to the company's quality goals, the quality inspection target of quality assurance is: “100% of the main products pass rate”. In combination with the production department and the department's quality goals, the production department determine the implementation measures and management methods. Product monitoring and measurement in the production process, from the raw materials to the delivery of finished products. The quality is strictly controlled in the whole process, and the unqualified products are not allowed to deliver.

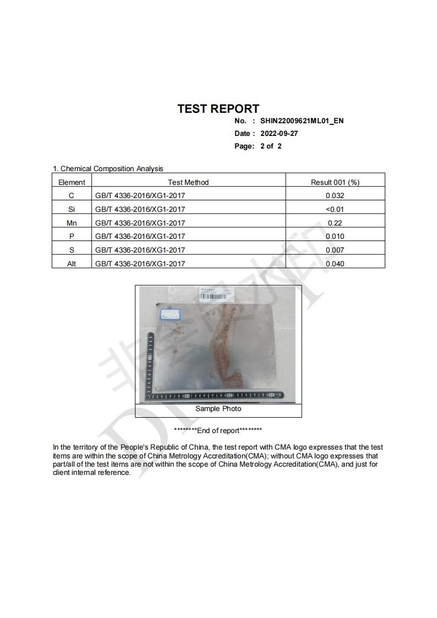

1. Supplier Quality Control

![]()