About Us

All Products

-

Cold Rolled Stainless Steel Sheet

-

Seamless SS Pipe

-

Stainless Steel Coil

-

Stainless Steel Round Bar

-

Galvanized Steel Pipe

-

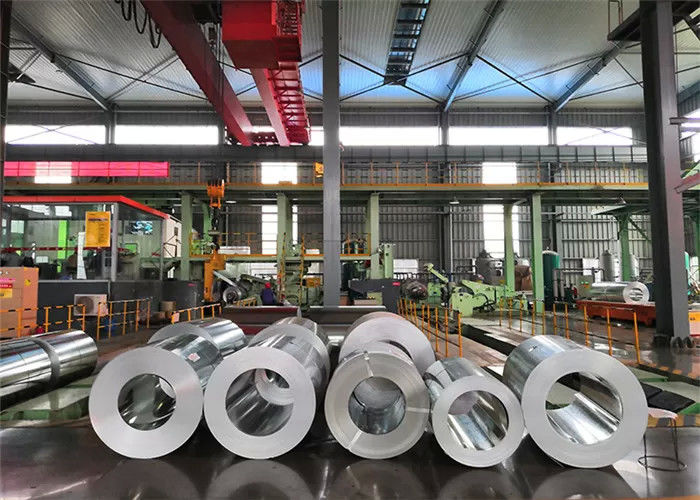

Galvanized Steel Coils

-

Galvanized Steel Sheet

-

PPGI Steel Coils

-

Steel Tin Plate

-

Mild Steel Square Tube

-

Carbon Steel Coils

-

Carbon Steel Sheets

-

Wear Resistant Steel Plates

-

Aluminum Steel Sheet

-

Copper Steel Pipe

-

Copper Steel Bar

-

Copper Sheet Coil

-

Structural Steel Profiles

Production Line

Our company has been engaged in steel industry for more than 10 years.Full of experience and strong business relations with our customers and factories. And our products include galvanized steel sheet,Patterned galvanized steel plate ,angle steel, galvanized steel coil, galvanized square pipe, galvanized angel bar,galvanized channel steel,Alloy plate,high-pressure vessel plate ,galvanized steel pipe and wear resistant steel plate.

The main task of steelmaking is to adjust the content of carbon and alloying elements in the steel to within the specified range according to the quality requirements of the steel being made, and to reduce the content of impurities such as P, S, H, O, and N to the allowable Under the limit. The steelmaking process is essentially an oxidation process. The excess carbon in the charge is oxidized and burned into CO gas to escape, and other Si, P, Mn and other components are oxidized and enter the slag. Part of S enters the smelting slag, and part of it generates SO2 and is discharged. When the composition and temperature of the molten steel reach the required process, the steel can be tapped. But in order to remove excess oxygen in steel and adjust its overall chemical composition, deoxidizers and iron alloys or alloy elements can be added.

After a series of treatments, such as desulfurization and slag blocking, the delivered molten iron can be poured into the converter as the main charge. In addition, less than 10% of scrap steel will be added. Then, oxygen is blown into the converter to burn, the excess carbon in the molten iron will be oxidized and a large amount of heat will be released. When the probe measures the low carbon content we predetermined, it will stop blowing oxygen and tap steel. Generally, operations such as deoxidation and composition adjustment are required in the ladle; then the carbonized rice husk is thrown on the surface of the molten steel to prevent the molten steel from being oxidized again, and it can be sent to the continuous casting or die casting area. For some steel grades with higher requirements, you can increase bottom argon blowing, RH vacuum treatment, powder spraying (spraying SI-CA powder and modified lime), which can effectively reduce the gas and inclusion content in the steel, and further reduce The role of carbon and sulfur reduction. After these refining measures outside the furnace, the composition can be finally fine-tuned to meet our demand for high-quality steel.

The main processing methods of steel:

Rolling: The metal blank is passed through the gap between a pair of rotating rolls (it can be of various shapes according to requirements). Due to the compression of the rolls, the cross-section of the material is reduced and the length is increased. This is also the most commonly used production for steel production. Method, mainly used to produce profiles, plates and pipes. Divided into cold rolling and hot rolling.

Forging: A pressure processing method that uses the reciprocating impact of a forging hammer or the pressure of a press to change the blank into the shape and size we need. Generally divided into free forging and die forging, it is often used to produce some large materials, billets and other materials with relatively large cross-sectional dimensions.

Drawing: It is a processing method in which rolled metal blanks (forms, tubes, products, etc.) are drawn through a die hole to reduce the cross section and increase the length. This method is mostly used for cold working.

Extrusion: It is a processing method in which metal is placed in a closed extrusion cylinder and one end is applied pressure to extrude the metal from a prescribed die hole to obtain a finished product with the same shape and size. This type of production method is mostly used to produce non-ferrous metals metallic material.

OEM/ODM

PRODUCTION SAWING

Production sawing is used to cut carbon, stainless, and aluminum long products to custom lengths. Sawing tolerances are typically +/- 1/16”, with variations possible for different products and finished length.

![]()

MITER CUTTING

In addition to straight cutting, O’Neal Steel offers miter standard and compound miter cutting. Miter saw cutting allows end users to order material in kit form and have cut-to-length and ready-to-weld pieces delivered to them.

Miter cutting is generally used for:

· Welding & fabrication

· Frames, tables & structural work

· Machine building

· Automation equipment

· Agriculture/Industrial equipment repair

PLASMA CUTTING

Plasma cutting is generally used for a metal thickness of about ½” and can be used for the high quality cutting of carbon steel, stainless steel and aluminum.

BENEFITS OF PLASMA CUTTING SERVICES

The various benefits to standard and high definition plasma cutting are:

· Speed – The cutting and piercing speeds of plasma cutting are several times faster than that of oxy fuel cutting. Faster cutting increases productivity and satisfies customers more because it decreases the time taken to get parts delivered.

· Precision – O’Neal Steel’s plasma cutting services are incredibly accurate. Our expert operators can achieve some of the tightest tolerances in the industry, providing the best product possible.

· Versatility – Plasma cutting can be used to cut various types of metal such as carbon steel, stainless steel, aluminum, copper and many more.

· Cost-Effectiveness – The speed, precision and versatility that come with O’Neal’s plasma cutting services is a very economical cutting method. It provides high definition and contour beveling capabilities to exact specifications at the lowest cost possible.

Plasma cutting is general used for materials in the following industries:

· Agriculture

· Automotive

· Commercial Construction

· Liquid Fertilizer

· Marine

· Medical

· Petrochemical

· Signage

STANDARD PLASMA CUTTING SPECIFICATIONS

Below are the standard specifications for high definition plasma cutting for aluminum, stainless steel and carbon steel.

OXY-FUEL CUTTING

Oxy fuel cutting, also known as flame cutting, is the most widely applied industrial thermal cutting processes. The process is used for cutting carbon plate from 5/8” through 12” thick and there are several fuel and nozzle design options that can greatly enhance cutting quality and speed. It is also cost effective because it can be used manually or mechanized.

O’Neal can cut parts from your drawings using DXF’s or manual programming.

THE OXY FUEL CUTTING PROCESS

A mixture of oxygen and the chosen fuel gas preheats the metal to its ignition temperature (which is well below its melting point). A jet of pure oxygen is guided into the preheated area, catalyzing an intense exothermic chemical reaction between the oxygen and the metal to create slag, or iron oxide. The oxygen jet then blows away this iron oxide, which allows the jet to pierce through the material and continue to cut through the metal.

For oxy fuel cutting to work, there are requirements that need to be met:

· The material’s ignition temperature must be lower than its melting point. If not, the material would melt before any flame cutting could be done.

· The oxide’s melting point must be lower than the melting point of the surrounding material to enable the oxygen jet to blow it away.

· The oxidation reaction between the jet and the metal must be adequate to maintain the ignition temperature.

· Small amounts of gaseous reaction products should be produce so that the cutting oxygen is not diluted in any way.

The most commonly used fuel gases for oxy fuel cutting are:

· Acetylene

· Propane

· MAPP (methylacetylene-propadiene)

· Propylene

· Natural gas

WHY OXY FUEL CUTTING?

Oxy fuel cutting brings much more than cost-effectiveness to the table. It provides high-quality cut and smooth, vertical planes of cut on material surfaces. The high heat input of the process allows carbonizing and hardening within the area of the heat affected.